Conveyor Belts

The variety of applications of conveyor belts is such that it ranges from the transport of food packages to the movement at docks, minerals and coal over long distances. Sometimes the length of these belts are several kilometers. Structure of conveyor belts such as rubber, EP fabric, metal (cord steel, ST) or (steel mesh, WI) protect upper and lower layers of cotton. These layers are resistant to abrasion by hard objects and corrosion due to contact with chemicals and heat. The adhesion of the layers is very important because it strengthen the conveyor belts. Adhesion causes that in different stages of work, such as carrying a load or rotating around the axis of the conveyor, the layers are not separated from each other and have the necessary flexibility.

All conveyor belts produced in this Complex can be closed edge or open edge based on the order.

Lightweight and Heavy Conveyor Belts

This type of conveyor belts is used to carry loads and light objects and packages in short distances such as: loading postal packages, moving and loading luggage and boxes of large and chain stores.

This type of conveyor belts is mostly industrial and specialized and is divided into two groups according to the place they are used:

General Uses

This type of conveyor belts is used in mining industries such as sand, gravel, gypsum, coal, iron ore and steel and cement. In this type of conveyor belts, the upper and lower layers are the same

Special Uses

These types of conveyor belts, depending on the type of use in specific places, have upper layers with different resistance to contact with sharp objects, acid, grease and heat.

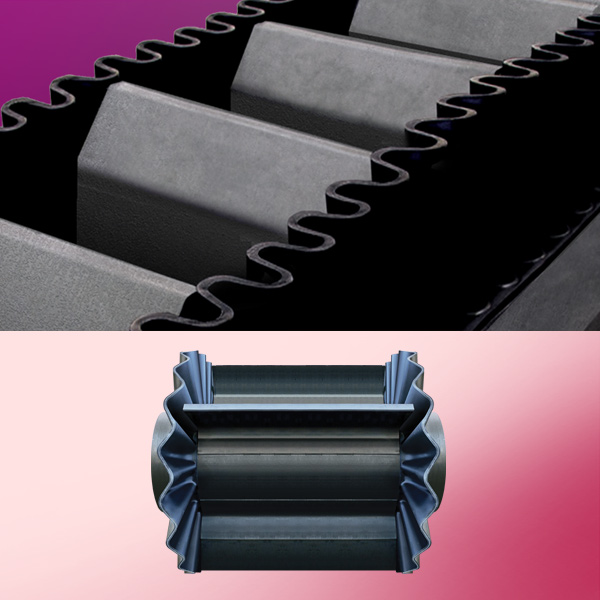

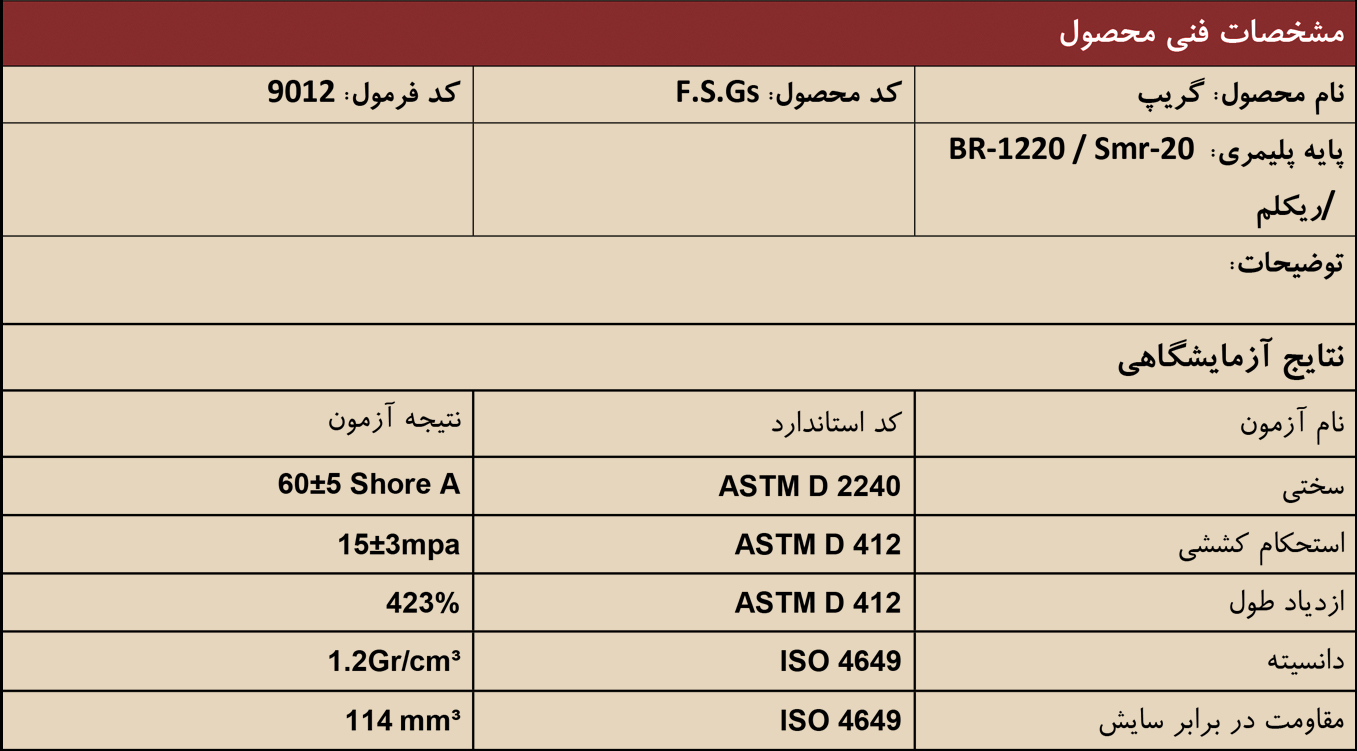

Chevron Conveyor Belts

This type of conveyor belts is used to transport goods and products at different angles and to prevent them from slipping or falling and protect them during transportation, a suitable tread must be used. It is noteworthy that according to the conditions and place of use of the conveyor belts, the appropriate tread and combination can be selected. In addition, the slope of the movement will be effective in choosing the tread of the conveyor belt. Its types are as follows:

Grip Conveyor Belts:

For transferring on slopes less than 45 degrees.

V pattern Conveyor Belts:

For transferring on slopes above 45 degrees and less than 70 degrees.

This type of conveyor belts has an upper surface with V pattern ridges with a height of 10 mm and distance of 20 cm.

These conveyor belts are produced with widths of 50, 55, 60 and up to 100 cm.

Shahin Conveyor Belts Complex is the only manufacturer of V pattern conveyor belts up to 100 cm wide in the country.

Conveyor Belts Dimensions

Conveyors in lengths of 100 m to 200 meters, thickness of 3 mm to 50 mm

Number of layers: 1 to 5 layers of cotton with different densities of GP100 to GP 250, width 60 cm to 160 cm

Simple Conveyor Belts

with width from 600 mm to 1600 mm, and thicknesses of 3 mm to 50 mm with 1 to 6 layers and different EPs from EP100 to EP2000 for use in light and heavy industries;

Special Conveyor Belts

Conveyor belts for special purposes (wear resistant, acid resistant, grease resistant, heat resistant conveyor belts).

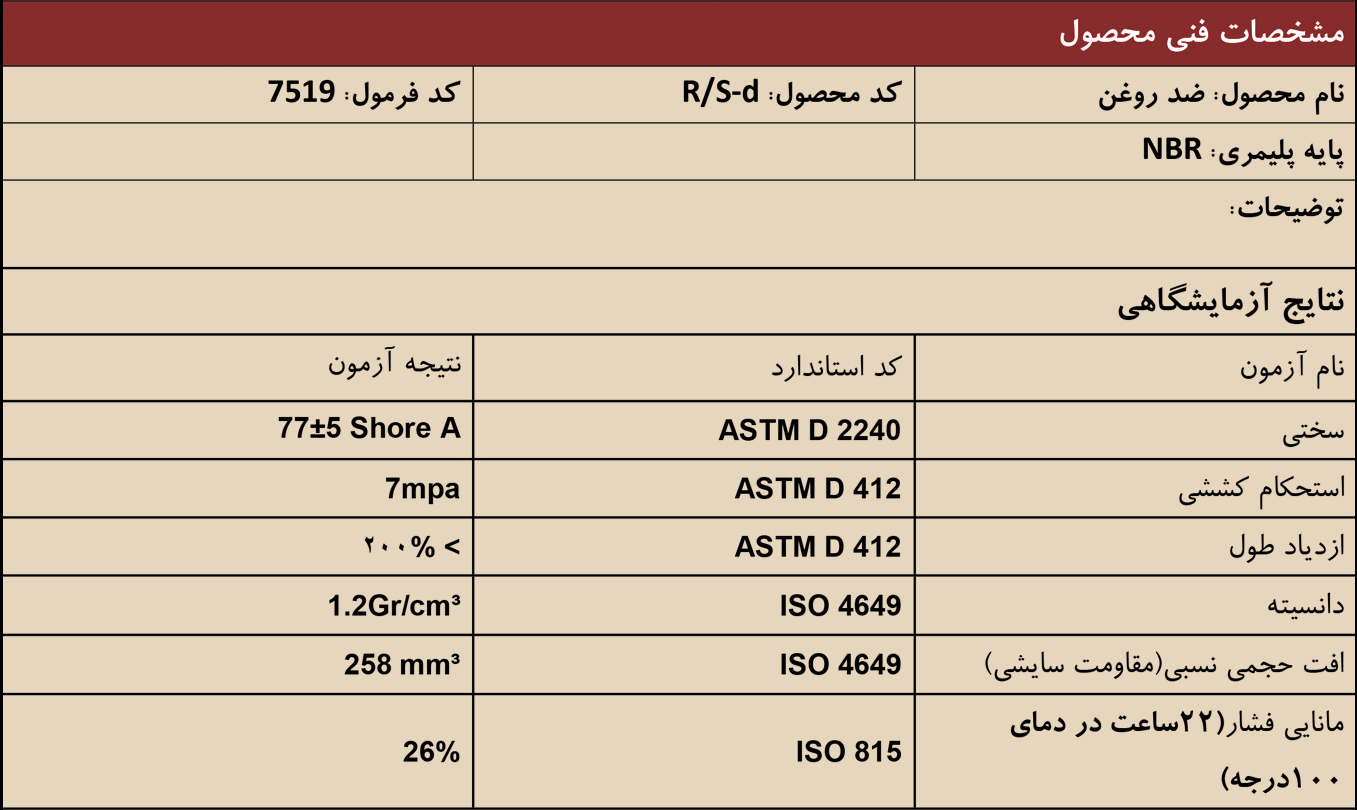

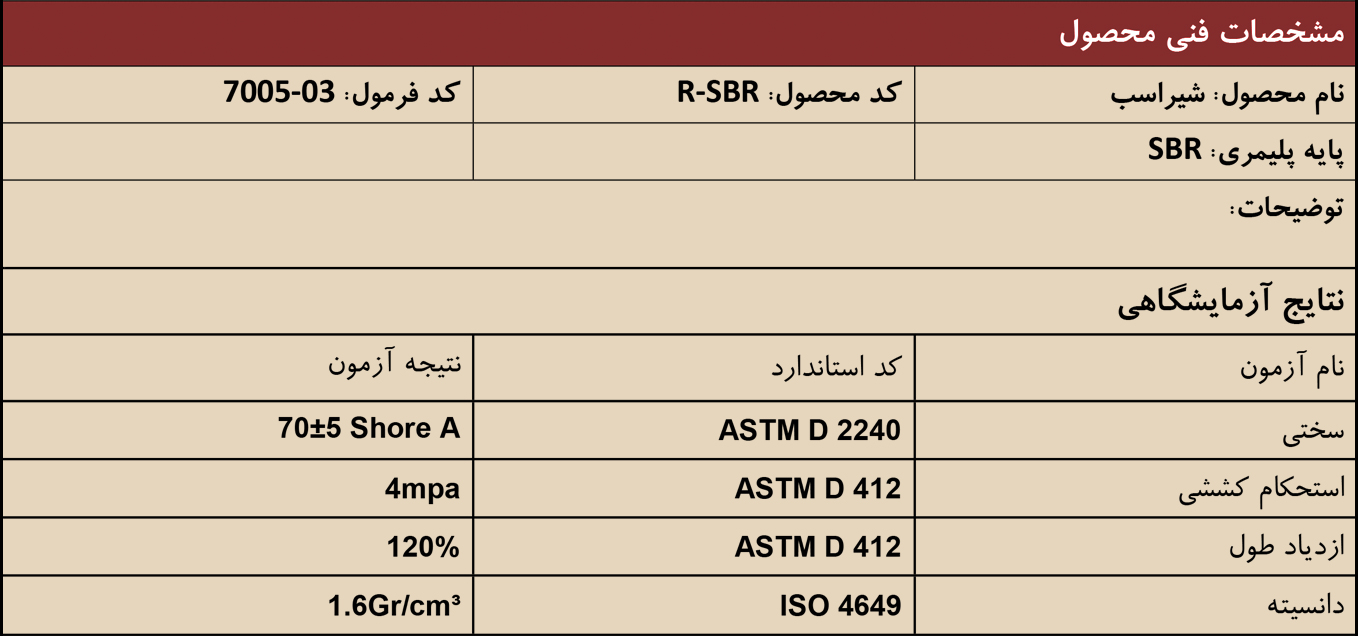

Classification Based on Compounds

-

Types of abrasion-resistant conveyor belts

The upper layer of this type of conveyor belts has a high resistance to wear and friction and makes it possible to carry abrasive materials and objects.

-

Types of conveyor belts resistant to grease

In this type of conveyor belt, the upper surface has special properties that are not vulnerable in contact with greasy materials and has a high resistance.

-

Types of heat-resistant conveyor belts

In this type of conveyor belts, the top layer has the necessary and desirable resistance to carrying objects and materials with high temperature.

-

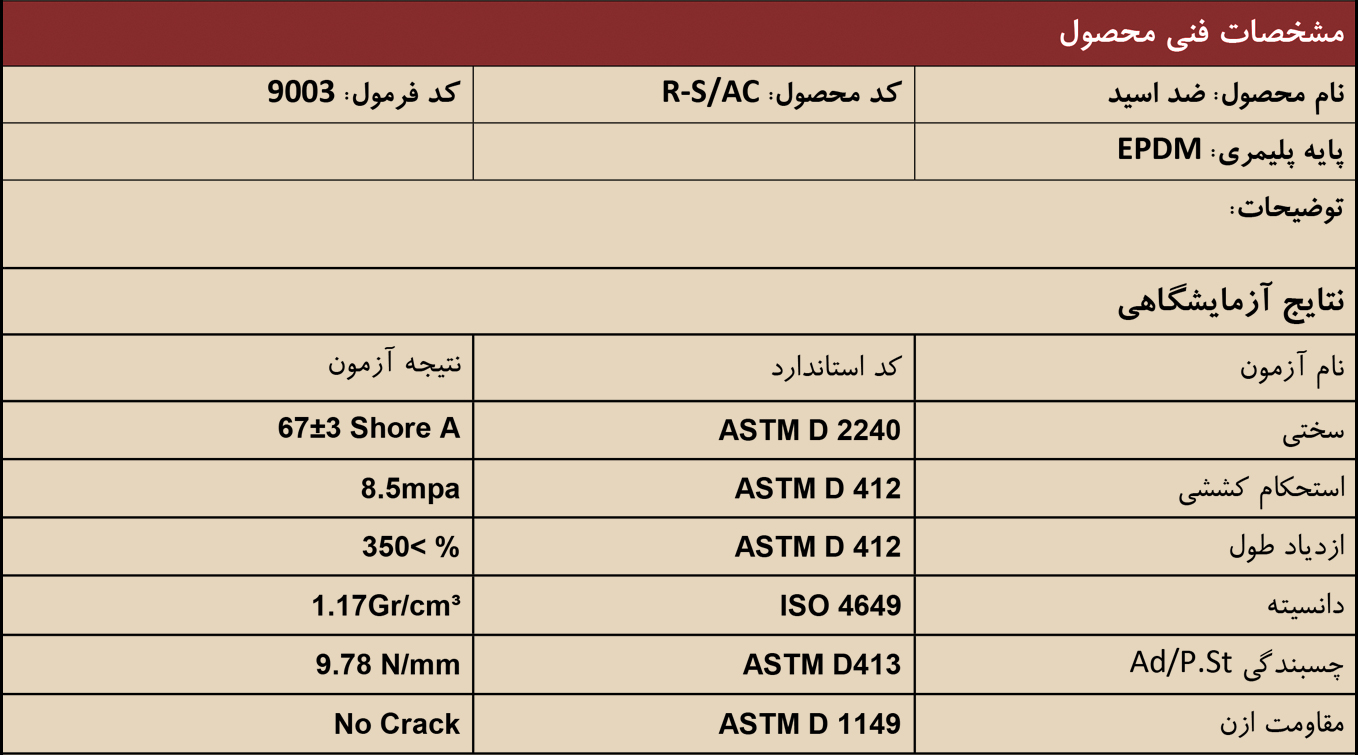

Types of conveyors belts resistant to acid corrosion and chemicals

Side Wall Conveyor Belts

It is used for vertical displacement of 90 degrees and its production requires special and complex design steps.

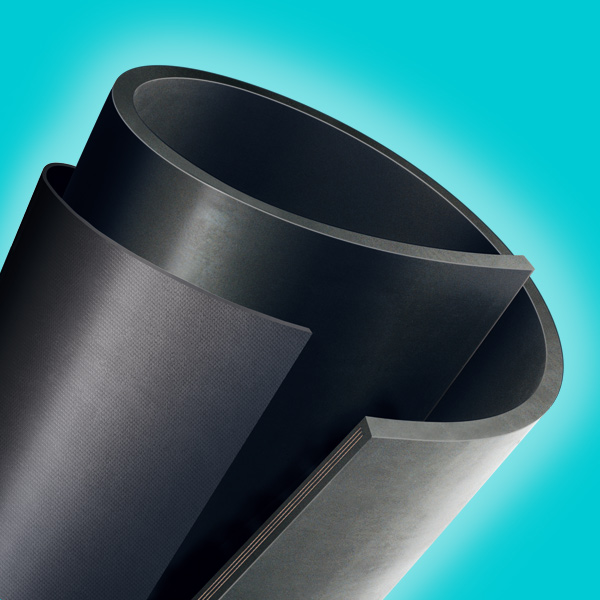

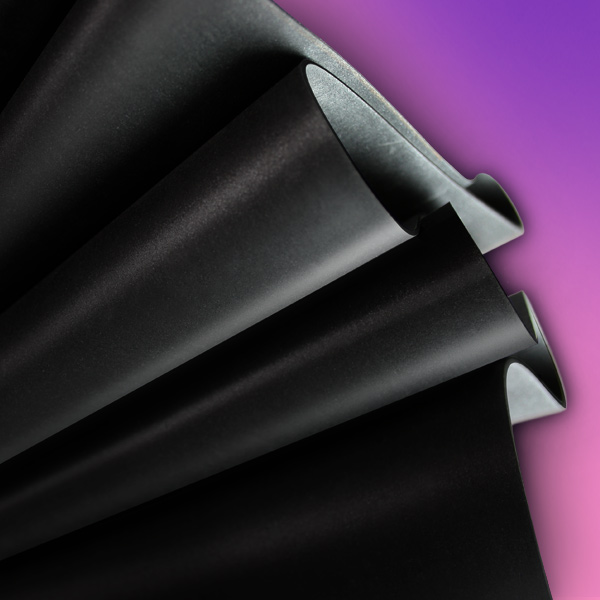

Rubber Sheets

armed with fabric and without fabric from width of 100 cm to 150 cm and thickness of 0.5 mm to 10 mm as one-side checkered, double-side checkered, and double-side smooth for use in various industries (oil, gas, petrochemical, water and sewage, refineries, etc.)

-

Rubber rolls with a width of 100 cm to 150 cm

It has one or more cotton layers or without cotton, one-side checkered, two-side checkered or two-side smooth. Thickness is between 0.5 mm to 50 mm

-

Rubber rolls with a width of 200 cm to 150 cm

Resistant to various types of grease, one-side checkered, or two-side smooth. (Raw or curing)

Thickness between 0.5 to 8 mm

-

Rubber rolls with a width of 100 cm to 150 cm

Resistant to acids and chemicals, one-side checkered, two-side checkered or two-side smooth. (Raw or curing)

Thickness between 0.5 mm to 8 mm

-

Rubber rolls with a width of 100 cm to 150 cm – heat resistant

Rubber liners – 80 cm to 150 width

Rubber Flooring

Anti-Slip Flooring:

One of the special products of Shahin Conveyor Belts Complex is anti-slip flooring, which is used for sloping, smooth and general slippery surfaces or at workshops, especially at outdoors and cold season. For example, we can mention yards of the pilgrimage places, passenger terminals, docks, hospitals, hotels, stairs of residential complexes, cinemas, theaters, water parks, etc.

Soundproof flooring:

This product, which is a joint production of Danesh Bonyan Company and Shahin Conveyor Belts Complex, is used in construction to prevent the transmission of sound from the floor and to eliminate this problem in apartments.

Rubber Lining

Rubber lining production and services for covering tanks: Petroleum and chemical transmission pipe lines, parts, jackets, risers, etc. are produced and used.

Factory address

Shahid Soleimani St., Khalij Fars St., Soheilieh road, Old Karaj – Hashtgerd road

Phone Number : 026 – 44454434 – 7

Fax: +98 26 4445 4438

Postal code: 3117338919

Sales Department Mobile: + 98 912 80 10 251 +98 912 35 95 688

Instgram : Shahin.Rubber

Linkedin : Info@Shahinconveyor.ir